Mechanical Seals and Dry Gas Seals

For Oil & Gas

ENPRO Africa is the authorized representative for Trem Engineering Mechanical Seals in Egypt and East Africa Region.

Trem Engineering is the leading Russian manufacturer of Mechanical Seals, Dry Gas Seals, and Mixer Sealing Solutions for Oil & Gas Industry based on Russian oil refineries reports.

The SD and RDT seals have won the trust of refinery engineers in Russia and nowadays about 70% of Russian major refinery critical process pumps are equipped with our seals with overall refining capacity 390.000 cubic meters a day has been analyzed.

Products:

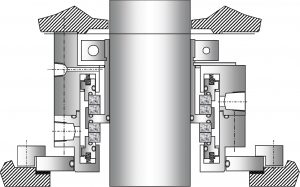

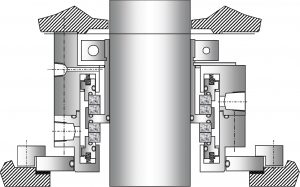

Mechanical Seal For Pumps

• O-ring or welded metal bellows mechanical seals API 682, Type A, C

• Single seals for oil and gas applications API 682 Type A

• Compact mechanical seals Type A

• Traditional mechanical seals (old models) API 682, Type A, B, C

Seal Systems

Seal systems for API 682 flush Plans 52, 53A, 53B, 65, 75, 23, and others.

Dry Gas Seals For Compressors

• Hydrogen compressors in hydrocracker units in oil refineries • Gas injection compressors in oil fields.

• Centrifugal compressors in natural gas pipeline transportation and networks.

• Upgrading from “wet” oil seals to dry gas seals includes seals, engineering, control panels and necessary new parts.

Mixers Solutions

• Bellows mixer seals for high pressure up to 200bar. • For sticky, abrasive, polymerizing fluids. • Seals for top, side, bottom vessel entry.

DLC coatings

• Hardness 1200- 4500HV

• Dry friction against steel 0.05-0.12

• Wear resistance is 13-20 higher than steel and 3-5 than tungsten carbide.

Mechanical Seal For Pumps

Seal Systems

• O-ring or welded metal bellows mechanical seals API 682, Type A, C

• Single seals for oil and gas applications API 682 Type A

• Compact mechanical seals Type A

• Traditional mechanical seals (old models) API 682, Type A, B, C

Seal systems for API 682 flush Plans 52, 53A, 53B, 65, 75, 23, and others.

Dry Gas Seals For Compressors

Mixers Solutions

• Hydrogen compressors in hydrocracker units in oil refineries • Gas injection compressors in oil fields.

• Centrifugal compressors in natural gas pipeline transportation and networks.

• Upgrading from “wet” oil seals to dry gas seals includes seals, engineering, control panels and necessary new parts.

• Bellows mixer seals for high pressure up to 200bar. • For sticky, abrasive, polymerizing fluids. • Seals for top, side, bottom vessel entry.

DLC coatings

• Hardness 1200- 4500HV

• Dry friction against steel 0.05-0.12

• Wear resistance is 13-20 higher than steel and 3-5 than tungsten carbide.