Montes

Air Treatment Systems and Tunneling Deduster

Montes is an Italian Air Treatment Systems and Sheet Metal working company offering skill, experience and flexibility for three generations. Our streamlined, flexible organization can plan, execute and control all the stages, from design up to after-sales service.

Air treatment systems

Our systems are used in these sectors to improve environmental quality in the workplace and productive process efficiency.

Filtration systems

We offer multiple filtration and purification systems to meet the specific requirements of every Customer.

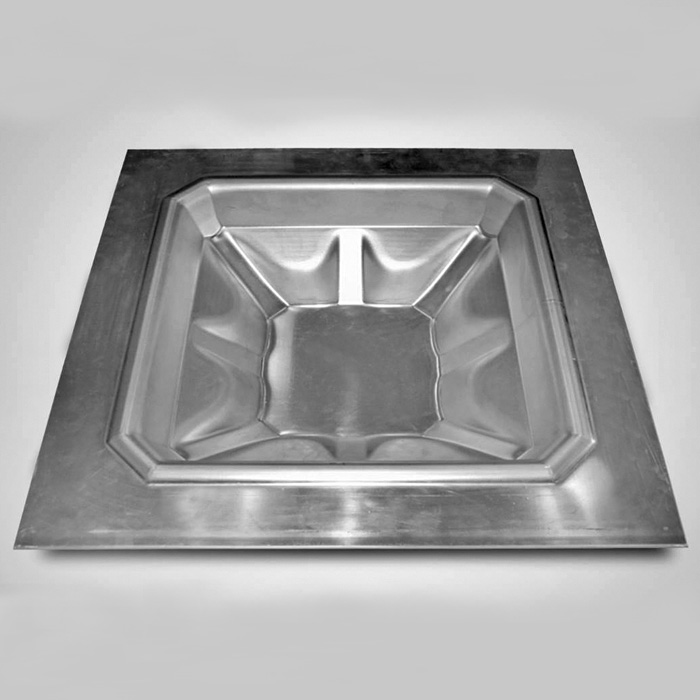

Incremental sheet forming

We were among the first in Europe to provide incremental sheet forming services, offering new opportunities in this area.

We have developed specific expertise in the supply of:

- Dust filtration systems

- Dedusting filters for tunnels and mines

- Suction systems

- Fume and solvent abatement systems

- Wet abatement systems

- Air conditioning systems

- Pneumatic transport systems for shavings, fibres, granulates

- Air re-circulation and heat recovery systems

- Self-cleaning cartridge dedusting systems

- Self-cleaning bag dedusting systems

- Self-cleaning rotating filters

Our production includes systems using dry and wet abatement technologies, which can be customized and dimensioned for each specific application.

Dry filtration:

- TMU series Tunneling and mining deduster

- CLD series Separation cyclone

- FCA series Self-cleaning cartridge deduster

- FMA series Self-cleaning bag deduster

- TWISTER series Toner suction booth

Wet filtration:

- SCRV series Vertical scrubber

- SCRO series Horizontal scrubber

With our incremental sheet forming service we provide the following services:

- Produce moulded pieces even if the quantity of pieces is not sufficient for amortising the cost of a mould

- Build functional prototypes directly from a CAD model

- Create pieces with shapes that improve the design of your products, overcoming the constructive limits imposed by traditional cutting, bending and welding processes on several parts

- Reduce times for prototype creation and therefore also reduce the time to market